The mechanical team was responsible for designing all structural components of the CanSat, which can be described by seven different subsystems. These include: Nose Cone (also functions as the heat shield), Landing Gear, Electronics Compartment, Egg Protection, Grid Fins, Streamer Release, and Parachute Release. During the competition, each of these subsystems serve a specific function in order to comply with a certain requirement, which gives us points towards our final ranking. Our job this year was to design, fabricate, test, (and redesign) each of these subsystems until they functioned reliably and robustly, and then integrate them into a full structure.

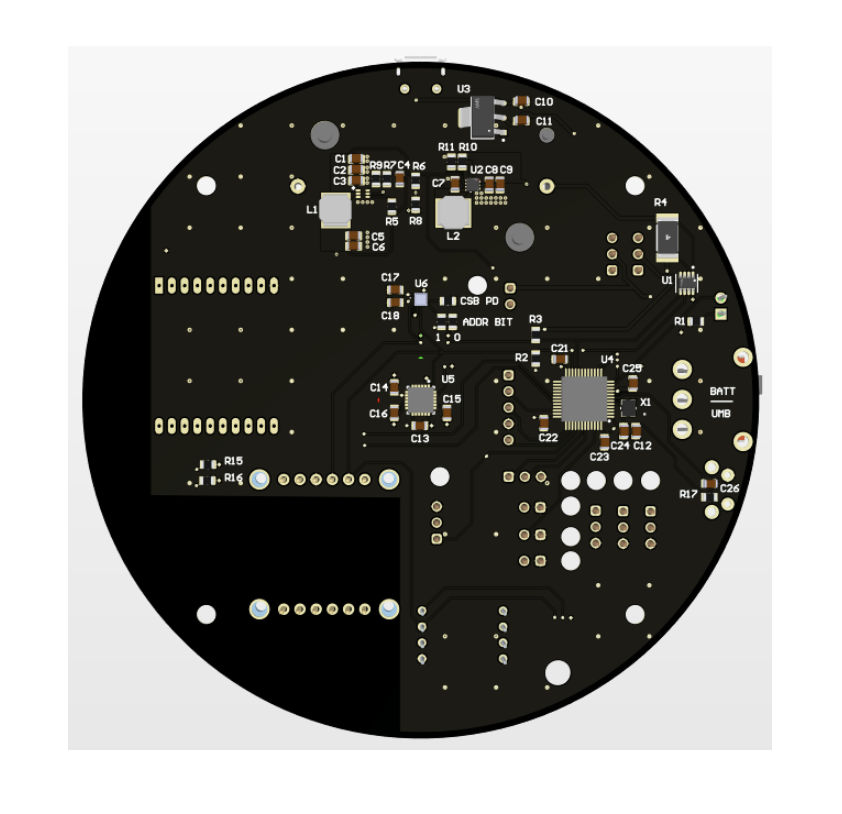

The electrical team was responsible for developing the avionics printed circuit board (PCB). This PCB connects various sensors and actuators, GPS, and radio to the main microcontroller (an STM32F1). After outlining requirements, conducting trade studies, and selecting components, we began designing the PCB in Altium Designer. We went through three iterations in total, reducing weight, improving RF performance, and making small mechanical improvements along the way. We hand soldered all PCBs to reduce the cost of the iterative process we followed. As part of this process, we focused on first developing a minimum viable product (achieved in revision two) so that we would be able to launch should any following revisions fail. Thankfully, all of the improvements we implemented in revision three were executed successfully, and we plan to launch with this version.

Figure: The final PCB iteration, Revision 3

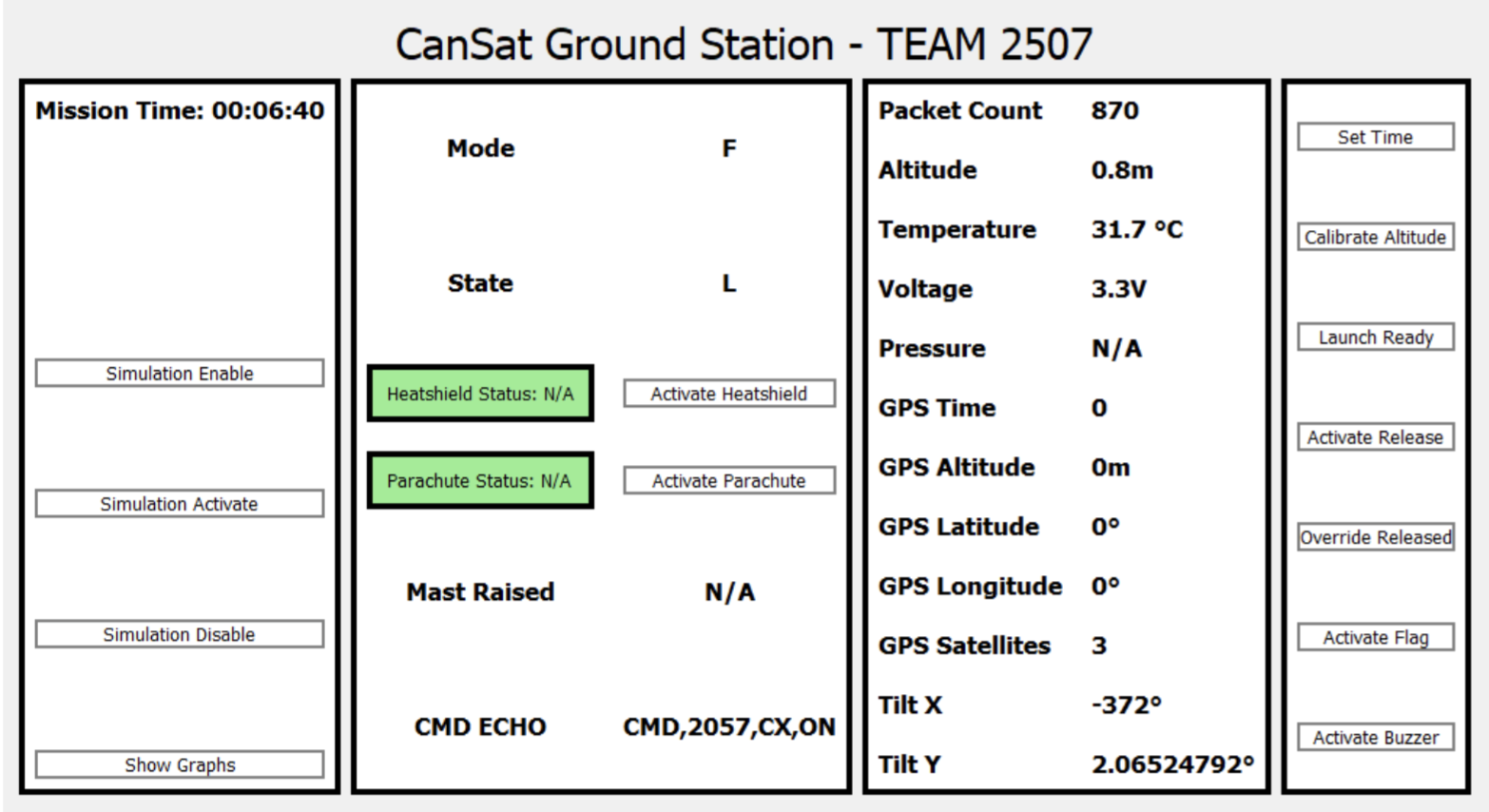

The controls subteam focused on designing and implementing the ground station program using PyQt5, adhering to the CanSat competition mission guide. The ground station interface, which includes commands like “Activate Heatshield” and “Activate Parachute,” communicates with the CanSat, displays received data, and controls operations. A “Simulation Mode” was also developed to test functionalities by mimicking flight data. Real-time data graphs on the ground station were designed and implemented using PyQtGraphs. Another main controls task is developing embedded systems for the CanSat payload using the electrical schematics provided by the electrical subteam. The embedded software, written in C, will run on the STM32 microcontroller.